You can choose the model according to the demand, the model is different, the price and capacity are not the same, the details can consult customer service*sunflower—cleaning—crushing—softening—flaking—drying—to extraction workshop

cleaning screen and de-stoner (sunflower oil press production line)

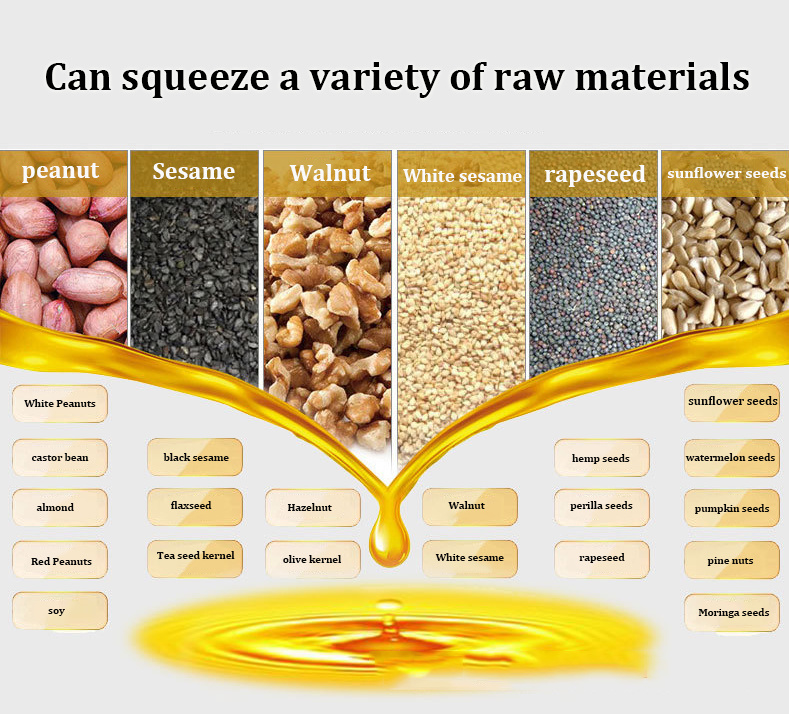

Product Application

Oil press machine for a wide variety of seeds including dried larvae .

The multifunctional oil press uses the action of mechanical external force to make the oil distributed on the inner and outer surfaces of the material embryo generate heat after being pushed and squeezed by the screw shaft, and escape from the adsorption force of the material embryo and overflow. This process of squeezing out the oil is called oil extraction.

This oil press machine can process many different oil seeds, such as sunflower seed, peanut, soybean, cotton seeds, sesame seeds, Canola, Copra, Palm kernel, Castor seeds, Corn germs, Mustard seed, Moringa seed etc different oil seeds. If you want to process other seeds or materials, feel free to contact us, we’ll recommend the right oil machine for you.

Working Principle

Performance advantages of oil press

3. All purpose press, one machine for multiple purposes. It can squeeze peanut, soybean, rapeseed, cottonseed, oil sunflower, tea seed, Tung seed, castor, almond, hemp seed, safflower oil seed and other oil crops.

The press method of multi-functional oil press for various oils: