Evaluation of Oil Extraction on Corn Dry-Milling

Dry Milling Process. The first step in the dry milling process is to remove any debris from the corn grain (i.e. corn stalk) using a process of screens (ICM, 2012). The entire grain kernel (fermentable and non-fermentable components) is sent through a hammer mill to be ground into course flour.

Get Price

Corn Milling Process | North American Millers' Association

The crude oil is then sold for further refining into edible oil. The oil-extracted germ cake, bran, standard meal, and broken corn are generally combined, dried, and ground into hominy feed. As the major by-product of the dry corn milling process, hominy feed is used as an inexpensive, high-fiber, high-calorie ingredient in animal feed.

Get Price

Dry milling and fractionation of grain

Currently, dry milling is mainly focused on corn based products for human and animal consumption, or utilized during fuel ethanol production. The main objective of the dry milling process is to separate the endosperm , which is mainly composed of starch , from the

Get Price

Dry and wet milling of corn - SlideShare

CORN DRY MILLING Dry milling process consists of the following steps: Cleaning Conditioning Degerming Drying Cooling Grading Grinding 4. Cleaning When corn is received at the mill, it is cleaned by both dry and wet process.

Get Price

Corn wet-milling

The corn wet-milling is a process of breaking corn kernels into their component parts: corn oil, protein, corn starch, and fiber. It uses water and a series of steps to

Get Price

Corn Oil 2006 - Corn Refiners Association

corn oil is from the corn wet milling industry, and all but a small fraction is used in one corn wet milling process, show-ing the paths of the corn kernel through equipment, processes, Dry Germ Oil Expellers and Extractors Crude Oil Oil Refining (See Fig. 3) Corn Germ Meal

Get Price

Jf,Properfies and Processing of Corn Oils Obtained by

the tocopherol present in whole grain was found in the oil after wet milling, and 73% was recovered after dry milling. As reported previously (5), phospholipids show little if any solubility in SC-C02. The phosphorus contents of SC-C02-extracted wet- and dry-milled oils are exceedingly low (1-5 ppm) compared to 120 ppm phosphorus for ex

Get Price

How to Extract Oil From Corn | LEAFtv

Corn oil is generally made using a combination of natural and chemical processes that ultimately separate the oil in the germ of the corn from the rest of the plant materials. You can make your own corn oil at home if you must, but it will not be the most efficient way to make use of your corn crops.

Get Price

Corn Oil Production Technology Report

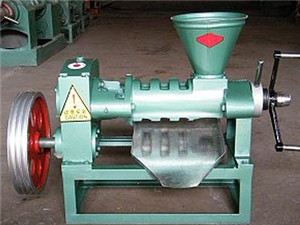

The operation of the corn germ solvent extraction, purification, evaporation and solvent recovery is conducted as normal solvent extraction process. Aqueous enzymatic corn oil making; The aqueous enzymatic solvent extraction technology is a process that extracts oil from plants with a mixed liquid of water and enzyme.

Get Price

Corn Oil Refining Process

Following is pretreatment of corn oil refining process. Crude corn oil that contained 380 ppm of phosphorus and 5% of free fatty acids was degummed, bleached, and winterized for physical refining. The pretreatment and the steam-refining conditions were studied in pilot plant scale (2 kg/batch).

Get Price

Use of Phytases in Ethanol Production from E-Mill Corn

Improvements especially in dry milling and enzymes products to allow better use of the starch in the corn kernel has been performed to increase the glucose conversion to ethanol [46, 47]. Enzymes

Get Price

US20020151733A1 - Products comprising corn oil and corn

Methods of manufacturing and processing corn oil and corn meal obtained from whole corn are included in useful products. The corn oil is extracted from the whole corn to form the corn meal. The corn oil generally comprises levels of nutrients not found in commercially available corn oils, since most or all of the corn grain, rather than just the germ, is exposed to the extraction process.

Get Price

Fuel Ethanol Coproducts for Livestock Diets

The corn wet milling process has been thoroughly reviewed by Johnson and May (2003). This process (Figure 1) consists of Corn germ meal results from the solvent extraction of the oil from whole corn germ. It is often high in fiber with moderate levels of CP, fat, and starch (Table 1). steep liquor is often high in phosphorus, potassium

Get Price

Aqueous Fractionation of Dry-Milled Corn Germ for Food

Aqueous Fractionation of Dry-Milled Corn 1000 per ton whereas germ meal (residues after oil extraction containing the germ protein) is sold for animal feed at $90 100 per ton. There is an opportunity to further Wet-milling yields high purity germ, but process conditions (pH and reducing agents) denature most of soluble germ proteins

Get Price

Changes in mineral concentrations and phosphorus profile

in corn wet-milling streams but did not study dry-grind streams. Belyea et al. (2006) was the first to examine changes in mineral composition during the dry-grind process within a plant and the

Get Price

US20090181153A1 - Dry-Mill Ethanol Plant Extraction

In dry milling, the entire starchy grain, commonly corn, is first ground into flour, which is then mixed with water to form a mash, heated to reduce bacteria levels prior to fermentation, and cooled.

Get Price

Handbook on Drying, Milling and Production of Cereal Foods

yields of products, roller milling: flour extraction rates, rice production and utilization, origin of rice, Dry Corn Milling The Tempering-Degerming Milling Process Products from the Tempering-Degerming Process Wet Corn Milling The Wet-Milling Process

Get Price

Dry milling and fractionation of grain

The corn wet-milling is a process of breaking corn kernels into their component parts: corn oil , protein , corn starch , and fiber . It uses water and a series of steps to

Get Price

Phosphorus Bioavailability, True Metabolizable Energy, and

Corn germ meal (CGM) is a by-product from corn industry obtained after extraction of corn oil and has nutritional characters (with medium energy and protein) for inclusion in livestock and poultry

Get Price

Milling By-Products of Cereal Grains - Oregon State University

Wet milling of corn is a more extensive process than dry milling. Figure 5.4 illustrates an overview of the wet corn milling process. In brief, wet milling involves cleaning, steeping, grinding, extraction, other separation processes, and drying of the products.

Get Price

Value and Use of Corn Milling By-Products In the Cow Herdv

This paper will discuss the wet and dry milling process, product quality, nutrient quality, and research on use by beef cattle. corn grain is typically 4% oil or fat, wet or dry distillers grains are about 12% fat and phosphorus. Corn gluten feed is between 19 to

Get Price

Biodiesel production from corn oil: A review - ScienceDirect

Oil yields from wet-milled corn germ, dry-milled corn germ and corn fiber by n-hexane extraction are 40–50%, 20–25% and 2–3% (based on a dry weight) respectively, while oil yield from ground or flaked whole corn by ethanol extraction is 3–5% .

Get Price

The problem with corn oil biodiesel - Biodiesel Magazine

Under the RFS, biodiesel from NFG corn oil qualifies for federal credits if the oil is produced at a dry-mill corn ethanol plant by extraction from the distillers grains coproduct. There are no credits for renewable fuel from corn oil derived by fractionation at a dry-mill ethanol plant, or corn oil derived from wet milling.

Get Price

Biodiesel production from corn oil: A review - ScienceDirect

Oil yields from wet-milled corn germ, dry-milled corn germ and corn fiber by n-hexane extraction are 40–50%, 20–25% and 2–3% (based on a dry weight) respectively, while oil yield from ground or flaked whole corn by ethanol extraction is 3–5% .

Get Price

The problem with corn oil biodiesel - Biodiesel Magazine

Under the RFS, biodiesel from NFG corn oil qualifies for federal credits if the oil is produced at a dry-mill corn ethanol plant by extraction from the distillers grains coproduct. There are no credits for renewable fuel from corn oil derived by fractionation at a dry-mill ethanol plant, or corn oil derived from wet milling.

Get Price

Manure Matters - Role of the Grain Processing Industries

subsequent extraction of the corn oil. The remaining grain fraction is then finely ground and In the dry milling process, dry grain (usually corn and sorghum grain in Nebraska) is ground and then combined with water concentration was .45% of the diet dry matter. Although phosphorus is an issue with the use of grain milling byproducts

Get Price

Pilot-Scale Supercritical Carbon Dioxide Extraction and

stages of the process. Extraction of wheat germ with liquid and SC-CO2 (5–40 MPa) at relatively low temperatures When SC-CO2-extracted corn fiber oil, which is also rich in phytosterol esters (especially oryzanol), was fractionated using a flow indicator, and finally through a dry gas test meter (Model DMT-200A-3; American Meter

Get Price

Corn gluten meal

Corn gluten meal is a by-product of the manufacture of maize starch (and sometimes ethanol) by the wet-milling process ().Corn gluten meal is a protein-rich feed, containing about 65% crude protein (DM), used as a source of protein, energy and pigments for livestock species including fish.

Get Price

Corn Wet Milling: Separation Chemistry and Technology

SUMMARY Corn wet milling is a complicated, large-scale, and efficient industrial process designed to separate the chemical components from corn kernels. The success of wet milling, in terms of maximum yields, is largely dependent on the success of the steeping process.

Get Price

Mycotoxin Testing Ranges (ppb)

the corn kernel from which part of the oil has been removed and is the product obtained in the dry milling process of manufacture of corn meal, corn grits, hominy feed, and other corn products. §15051.

Get Price

MF2488 Corn Gluten Feed: Composition and Feeding Value

Composition and Feeding Value for Beef and Dairy Cattle. Corn gluten feed (CGF) is a by-product of the wet milling process. approximately 85% of the corn’s oil, are pumped onto screens and repeatedly washed milling process.a Wet Dry Nutrient Corn CGF CGF Dry matter, % 88 42 - 44 90

Get Price

Ingredients | Feed Ingredient Trading Corp.

A co-product of the corn wet milling process, corn gluten feed is a medium-protein, medium-energy feed ingredient. In beef cattle, studies indicate that corn gluten feed contains 87% of the feed value of dry corn.

Get Price

The Current Usage of DDGS and Corn Oil in Poultry Diets

Dry Milling Fuel Ethanol Process . Mid-Missouri Energy Ethanol Plant Malta Bend, MO . 0.0 5.0 10.0 15.0 20.0 25.0 30.0 Corn Oil Extraction? Dr. Bob Loar’s comments The Current Usage of DDGS and Corn Oil in Poultry Diets Author:

Get Price

Animal Feed Pellet Machine for Oil-cake from Edible Oil

The oil content of oil cakes from physical oil pressing is generally higher than oil cakes from solvent extraction. Oil cakes from oil pressing process is high in energy, which includes 5%~10% of crude fat, but easily oxidized.

Get Price

Corn Germ Meal (CGM) – Potential Feed Ingredient for

Additional end products from the wet milling process include several feed co- products like dry corn bran, corn gluten feed, corn gluten meal, corn germ meal, and steep liquor or condensed fermented corn extractives (CFCE) (Loy and Wright, 2003).

Get Price

Using Corn Distillers By-Products in Turkey Rations

Extraction Corn Oil Starch and Nutritive Sweetners Corn Gluten Meal Gluten Feed Corn Germ Meal Corn Corn Dry-Milling Process Overview alpha amylase enzyme CO 2 Yeast and Glucoamylase Enzyme whole stillage Phosphorus levels can be in excess in combination with

Get Price

Corn Survey Violations

the corn kernel from which part of the oil has been removed and is the product obtained in the dry milling process of manufacture of corn meal, corn grits, hominy feed, and other corn products. §15051.

Get Price

Changing distillers grains: implications for cattle

with the first method being corn oil extraction. Because of these advancements in the ethanol production process, the nutrient profile of DG has begun to change.

Get Price

Distillers Grains FAQ’s - Iowa Renewable Fuels Associations

The current market price and demand for crude corn oil is very attractive as another revenue source for ethanol production facilities and the availability and relatively low cost of adding oil extraction equipment to existing ethanol plants makes this process very profitable.

Get Price

Animal nutrition Plant and animal tissues + Feedstuff

The major industries that process grains for human consumption and produce co-products for use in animal feeds are the brewing, distilling, wet milling and dry milling industries. Some of the co-products are energy feeds; however, some are protein supplements or roughages.

Get Price

Corn By-Product Diversity and Feeding Value to Non

Corn By-Product Diversity and Feeding Value to Non-Ruminants Jerry Shurson1, Sally Noll1, Extraction Corn Oil Starch and Nutritive Sweetners Corn Gluten Meal Gluten Feed Corn Germ Meal Cond. Fermented Extractive. Corn Corn Dry-Milling Process Overview alpha amylase enzyme CO 2 Yeast and Glucoamylase Enzyme whole stillage thin stillage

Get Price

Maize Processing |authorSTREAM

Contrary to the dry-milling process, the wet-milling process uses large amounts of water to steep kernels and thereby separates out the germ, and then separates the germ into oil and meal; (100 grams of maize produces about 3 grams of oil.

Get Price

Fuel Ethanol Coproducts for Livestock Diets› Dairy Cattle› Technical articles› Nutrition

Corn germ meal results from the solvent extraction of the oil from whole corn germ. It is often high in fiber with moderate levels of CP, fat, and starch (Table 1). Corn germ meal is highly digestible and is a common ingredient in non-ruminant diets.

Get Price

Changes in Composition and Amino Acid Profile during Dry

Results from Plant 1 samples showed that compared to ground corn, there was a slight but significant increase in the contents of protein, amino acids (AA), oil, and ash before fermentation, although starch/dextrin decreased sharply upon saccharification.

Get Price

Effects of Feeding Reduced-Fat Modified Distillers Grains

(protein, oil, fiber, ash, and phosphorus) in whole stillage are increased 3-fold in DGS when ethanol producers continue to seek greater value from corn grain being processed, oil extraction RFMDGS utilized that was processed by a dry-milling process with back-end centrifugation of thin stillage and contained 8.81% EE (Big River

Get Price

Corn distillers grain

Corn distillers grain. The dry-milling (or dry-grind) process is the main process for producing ethanol. This process starts with removing the bran by grinding before steeping the grain in water and results in ethanol and various "distillers" by-products. The extraction of maize oil from distillers dried grain is less costly than direct

Get Price

Products from corn — Vikaspedia

The last stage of the multi-step cyclone plant is the one and only step of the wet milling process where fresh water is added. By optimal construction and adjustment of the plant it is possible to reduce the protein content in the starch below 0.3 % on dry matter. The meal is then heated to facilitate the extraction of the oil. While the

Get Price

The Future of Coproducts From Corn Processing - CiteSeerX

by wet milling; however, in the past 10 yr, dry-grind capacity has increased rapidly and now accounts for 70% of ethanol production (1) . Recent growth trends in the dry-grind ethanol industry are expected

Get Price

Oil extraction method and composition for use in the

Most commercial corn oil is produced by front end fractionation of corn germ during the wet mill corn process. Recently, a new source of corn oil has arisen as a by-product of the dry-mill process used in the ethanol industry.

Get Price