Sunflower Oil Refining Process | Sunflower Oil Refining

Sunflower oil refinery plant includes a series process, such as degumming, neutralization, bleaching, deodorization and dewaxing Goyum is a well-known manufacturer of full-line sunflower oil refining plant.

Get Price

Sunflower Processing - Crown Iron Works

The sunflower oil can be further refined from a crude product to an edible product. Oil Refining and Processing Extracted and desolventized sunflower oil must be further processed to

Get Price

Processes Involved in Sunflower Seed Oil Production

Sunflower seed oil production does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil.

Get Price

Sunflower Oil Extraction Machine_Oil Pressing, Extraction

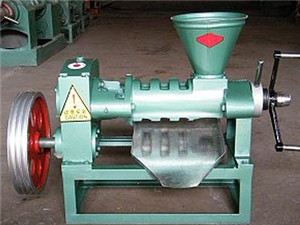

Golden sunflower seed oil, refreshing texture, it contains vitamins A, B, D and E, and rich in unsaturated fatty acids. The basic process: sunflower seed leaning---shelling—crushing---cooking—pre-pressing---sunflower oil extraction by solvent---sunflower oil refinery----filling.

Get Price

Sunflower Oil Production Line for Sunflower Oil Plant to

Sunflower Oil Production Process Introduction. Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body, and is beneficial to

Get Price

Edible oil refining | Cavitation Technologies, Inc.

Edible Oil Refining. Vegetable oil refining facilities process crude oils such as soybean oil, palm oil, rapeseed oil, canola oil, sunflower oil and other specialty oils including: peanut oil, olive oil and cottonseed oil. The processing converts them into oil for various consumer and industrial uses, for example, cooking oil, flavor enhancements and food additives.

Get Price

Chapter 5 : Processing and refining edible oils

The, b-carotene in palm oil is another valuable component that needs consideration in the refining process. Special processes for retention are being designed. Olive oil and sesame oil are used in unrefined form since a specific taste is expected by consumers.

Get Price

Sunflower oil refinery plant-refined sunflower oil machine

Sunflower oil refinery plant includes a series process,such as degumming, neutralization, bleaching, deodorization and dewaxing. In general there are two methods of sunflower oil refining, one is physical refining and the other is chemical refining.

Get Price

Sunflower oil refinery,sunflower oil refinery process

Automatic sunflower oil refinery is a little different with other vegetable oil refining, because sunflower oil contains too much wax, then except normal vegetable oil refining process, we need add dewaxing after oil refined in sunflower oil refinery process.

Get Price

Sunflower Oil Production Line for Sunflower Oil Plant to

Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body, and is beneficial to protect cardiovascular health.

Get Price

Vegetable Oil Refinery, Oil Refining Plant, Oil Refining

The degumming process described above produces a mixture of gums, oil, and water. The mixture of gums, oil, and water is introduced in a thin-film evaporator operating under vacuum to remove water. The resulting dry mixture of gums and oil is sold as crude dry gums or lecithin.

Get Price

sunflower oil refining process - Oil Mill Machinery

In order to obtain high-quality sunflower oil, the crude oil pressed by KMEC oil pressing plant must have the waxes as well as gums removed by using our sunflower oil refining process. In the finished product, these waxes would crystallize at low temperatures and make the oil turbid.

Get Price

What is the vegetable oil refining process?

Process Description of Vegetable Oil Refining is as follows. Water Degumming :-Water Degumming is first step in the Edible Oil Refinery Process. Oils contains Hydratable Phosphatide which absorb the water, that Hydratable Phosphatides are oil- insoluble which easily separated by centrifuge.

Get Price

Physical refining of sunflower oil | Request PDF

Crude sunflower oil was stored at room temperature and was regularly refined by applying physical refining process in laboratory scale studying lipid degradation. Effect of long-term storage and

Get Price

Turnkey Cooking Oil Refinery Plant | Manufacturer of

In batch oil refinery process or cooking oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching & deodorizing. For plants capacity from 5 to 25 tons per day, batch process is recommended being low cost and easy to operate.

Get Price

Sunflower Oil Refinery www.expeller-india.Get Price

Sunflower Oil Processing - Oil Mill Plant

Sunflower oil that is processed by our sunflower oil processing plant meets the needs of consumer and food manufacturers alike for a healthy and high performance non-transgenic vegetable oil. Available sunflower seed varieties fall into two major groups: confectionery and oilseed.

Get Price

Processes Involved in Sunflower Seed Oil Production

Sunflower seed oil production does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil.

Get Price

Feed - FEDIOL

EFISC Guide – Sector reference document on the manufacturing of safe feed materials from oilseed crushing and vegetable oil refining 81 Feed Risk assessment of the chain of sunflower seed meal and oil products 2. Drying of sunflower seeds at primary production* HAZARD CAT.

Get Price

Sunflower Processing - Crown Iron Works

Oil Refining and Processing Extracted and desolventized sunflower oil must be further processed to make an edible product. Edible oils are refined to improve the flavor, odor, color and stability using processes that degum , neutralize , bleach and deodorize the oil.

Get Price

Sunflower oil refinery plant-refined sunflower oil machine

Sunflower oil refinery plant includes a series process,such as degumming, neutralization, bleaching, deodorization and dewaxing. In general there are two methods of sunflower oil refining, one is physical refining and the other is chemical refining.

Get Price

Professional Sunflower Oil Manufacturing Process - Offered

Sunflower oil manufacturing process is a complicated oil making process. The detailed manufacturing process for sunflower seeds is as follows: The sunflower seed is the fruit of the sunflower which usually contains approximately 40 - 50% oil by weight.

Get Price

edible oil refining method and technology information in

What is edible oil refinery process? Usually oil refining process includes degumming,deacidifaction,decolorization and deodorization. Some special crude edible oil need dewaxing or fractionation like crude sunflower oil,crude cottonseed oil,crude corn germ oil,and crude palm oil.

Get Price

Sunflower Oil Refining Production Machinery Price

China Oil Refinery Machine catalog of Sunflower Oil Refining Equipment with PLC System for Soybean and Sunflower Oil Refinery Plant, Vegetable Oil Refinery Equipment /Oil Refining Plant/Sunflower Oil Refining Machine with Ce ISO provided by China manufacturer - Zhengzhou Sinoder Indutech Machinery Co., Ltd., page2.

Get Price

Turnkey Cooking Oil Refinery Plant | Manufacturer of

In batch oil refinery process or cooking oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching & deodorizing. For plants capacity from 5 to 25 tons per day, batch process is recommended being low cost and easy to operate.

Get Price

Sunflower Oil Processing - Oil Mill Plant

For economic reasons it is increasingly popular to start a sunflower oil plant for sunflower oil processing to make cheap sunflower seeds into more valuable and healthy sunflower oils. The sunflower is a distinctive, flowering plant (Helianthus annuus L.), the seeds of which contain a valuable edible oil that contains more Vitamin E than any other vegetable oil.

Get Price

Sunflower Oil Production Line for Sunflower Oil Plant to

Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body, and

Get Price

Refined Sunflower Oil - Gartner Ukraine

Refined sunflower oil is perfectly clean oil, which preserves all the nutrients during the production process. This oil can be used in conditions of extremely high cooking temperatures. Margarine and cooking fats are made of refined sunflower oil by hydrogenation.

Get Price

Physical refining of sunflower oil | Request PDF

Crude sunflower oil was stored at room temperature and was regularly refined by applying physical refining process in laboratory scale studying lipid degradation. Effect of long-term storage and

Get Price

Sunflower Seed Oil Refining Process In Sunflower Peanut

Sunflower oil refinery in ukraine/cooking oil refining process. Crude oil -- Refining workshop. The whole process of the sunflower oil processing line machine can be divided into. Send Inquiry; Sunflower Oil Production Line Wholesale, Production Line Suppliers .

Get Price

Edible Oil Refinery, Vegetable Oil Refinery, Cooking Oil

Edible Oil Refinery consists of Soyabean Oil Refinery Plant, Coconut Oil Refinery Plant and Sunflower Oil Refinery Plant. We also manufacture Small Scale Mini Oil Refinery and Batch Type Oil Refinery Plants from India. Tinytech is an Indian first class engineering company with leadership in executing process plants for Vegetable Oil

Get Price

manufacture of Sunflower oil refining machine_offer oil

offer oil mill plant Oil Refining Process,manufacture of Sunflower oil refining machine,Henan Doing Mechanical Equipment Co.,Ltd is specialized in sunflower oil refining machines. We could offer you batch & fully continous types of different capacities refining machines from 1t/d to 600t/d.

Get Price

#1 Edible Oil Refinery Plant Manufacturers & Exporters

Edible Oil Refinery Plant Manufacturers & Exporters. Muez-Hest is a technology development and EPC with a large part of our expertise pertaining to Edible Oil Refinery Plant Manufacturers & Exporters.. Edible Oil Refinery Plant requires precision of machinery while ensuring minimum addition of contaminants and odour producing agents.. Muez-Hest has worked tirelessly with many customers

Get Price

sunflower oil refining process - Oil Mill Machinery

Cold-refining which using KMEC sunflower oil refining process line is a matured method of obtaining refined sunflower oil from crude oil. This sunflower oil refining process combines neutralization and dewaxing to guarantee a high-quality edible oil.

Get Price

Oil Refinery Plant|Customized Edible Oil Refining Process

So called “refinery”, generally refers to deacidificationprocess. But in the broad sense, oil refinery process includes crude oil pretreatment, degumming, deacidifying, decoloring, deodorization, degreasing, and dewaxing process, etc. We will design the refining process depending on the quality requirements of

Get Price

sunflower oil refinery workshop | Oil Processing Equipment

Oil Refinery Plant|Customized Edible Oil Refining Process. 5TPD Sunflower Oil Refining. 10TPD Oil Refining Equipment. Decoloration. Deodorization Workshop. Depickling Department. Oil and Fat Refining. Degumming Process. Degumming Process. Oil Refining Department. Decolorizing Section. Oil Refining Tank.

Get Price

Manufacture of Continuous oil refinery plant_Oil Refining

Continuous oil refinery plant. 2017-10-10 16:57; Oil Refining Process; Get price; Continuous oil refinery plant . Continuous oil refinery plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content.

Get Price

Set Up a Full Sunflower Oil Processing Plant|Turnkey

Sunflower Oil Processing Plant HOME > Industry > Oil Pressing ABC Machinery is a well-known manufacturer of full-line sunflower oil machinery , mini, small and industrial large sunflower oil processing plant exporter in China.

Get Price

SUNFLOWER OIL REFINERY - PART I - Blogger

sunflower oil refinery - part i * This was a group project i worked on during my 1st year of Chemical Engineering at Newcastle University. This project won the "Best Project" award sponsored by BP as it was a simple yet comprehensive project outlining the refinery process, mass balancing and providing a preliminary cost analysis to produce

Get Price

Manufacture of 1-30tpd batch type vegetable oil refinery

1-30tpd batch type vegetable oil refinery plant is a process to remove unwanted and undesirable elements from the crude edible oil. The elements that are removed include the Free Fatty Acids, Phospholipids, Gums,Odour, Color, Waxes etc. 1-30tpd batch type vegetable oil refinery plant makes the vegetable oil clean and pure and improves the overall quality of the oil.

Get Price

Cooking Oil Refinery Plant - Batch Oil Refinery Plant 100%

Cooking Oil Refinery Plant 100% Export Oriented Unit of a wide range of products which include batch oil refinery plant, continuous edible oil refinery plant, sunflower oil refinery plant, vegetable oil refining plant, continuous edible oil refinery and cooking oil refinery plant.

Get Price

physical refining sunflower oil.pdf | Oil Refinery

As the crude sunflower oil contains . this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. on the other hand. which is not removable by bleaching and/or heat bleaching. The efficient removal of phosphatides is the keypoint in physical refining. .

Get Price

b) Listing of feed materials - EFISC-GTP

vegetable oil refining 5 b) Listing of feed materials sunflower seed oil) Soya (beans) and sunflower seeds may be dehulled, resulting in meal with a low sunflower and maize oil. This process is also referred to as dewaxing. 2.5. Deodorisation: chemical refining

Get Price

Manufacturer Sunflower seed oil refining machine

2. Crude sunflower seed oil refining process. Sunflower seed oil refining process. As the picture shows that through degumming, decoloring, deodorization, dewaxing, fractionation etc, the sunflower seed oil will be taken off impurity and we can get standard edible sunflower seed oil. At present, there are four grade standard s of edible oil, and different oil grades have different requirements

Get Price

SUNFLOWER OIL REFINERY - PART II

Working towards a goal of 20’000tonnes of Sunflower Oil to be produced by the end of each year, it is necessary to calculate roughly the reaction time in each process so that the size of reaction vessels required can be worked out.

Get Price

Edible Oil Refinery, Vegetable Oil Refinery, Cooking Oil

Edible Oil Refinery consists of Soyabean Oil Refinery Plant, Coconut Oil Refinery Plant and Sunflower Oil Refinery Plant. We also manufacture Small Scale Mini Oil Refinery and Batch Type Oil Refinery Plants from India. The crude coconut oil is allowed to be processed further on Tinytech Coconut Oil Refinery. In this process, our

Get Price

Oil Refining Plant,Vegetable Oil Refining Plant,Vegetable

Oils like sunflower oil or maize germ oil (corn oil) have waxes present in them. At low temperature these waxes gives hazy appearance to oil, which is not liked by consumers. It is therefore essential to remove these waxes prior to bottling and marketing of oil.

Get Price

Article Archives - National Sunflower Association Home

The decision to build an oil refinery was under consideration for some time, according to plant manager Rick Robbins. “After the industry changes to NuSun® and high-oleic sunflower, we knew we had to refine our oil at the plant to compete in the domestic market,” Robbins says.

Get Price