Refining crude soybean oil into refined oil | Wilmar

The resulting product is crude soybean oil. The crude oil is then refined via three stages: water degumming, chemical refining and physical refining. In water degumming, a sticky viscous oil-water emulsion or gum is removed by using water and a centrifuging process.

Get Price

soybean oil extraction plant manufacturer in zimbabwe

Refining crude soybean oil into refined oil | Wilmar. Miscella is distilled and filtered to remove hexane, which is recovered for re-use. The resulting product is crude soybean oil. The crude oil is then refined via three stages: water degumming, chemical refining and physical refining.

Get Price

Soybean Oil Refining

SOYBEAN OIL REFINING Jean-Paul Helme Consultant, Paris 1984 I. Introduction II. Crude Oil Quality III. Fatty Acid Composition of Soybean Oil IV. Triglyceride Structure V. Minor Constituents VI. Different Processes VII. Conventional Flow-Sheet of the Refining Process VIII. Effects of Processing on the Nutritive Value IX.

Get Price

crude palm oil refinery machine made in india in zimbabwe

crude palm oil refinery plant is used for transforming crude palm oil into refined palm oil, and we manufacturer & sale various capacity palm oil refinery plants.our palm oil refinery plants are exported to around the world. 50-1000tpd continuous palm oil refining machine is used for removing the harmful impurities in the crude palm oil

Get Price

Chapter 5 : Processing and refining edible oils

Investigations in which oil was maltreated under extreme conditions (Rossel, Kochhar and Jawad, 1981; Jawad, Kochhar and Hudson, 1983 a, b; 1984) determined the effects of temperature (240-300°C) and time (30-180 min.) during "physical refining" of soybean oil (degummed with phosphoric acid and lightly bleached, but still containing 20 mg P, 0.35 mg Fe and 0.05 mg Cu per kg oil).

Get Price

Soybean oil production

Counterflow is used as extraction system because it gives the highest yield. After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food products such as soy protein. The hexane is separated from the soybean oil in evaporators.

Get Price

Soybean Oil Refining & Detailed Soybean Oil Refining Process

The crude soybean oil still contains many oil-insoluble and oil-soluble impurities that needs to be removed. Soybean oil refining including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids, colorants, insoluble matter and gums) and bleaching (with activated earth or activated carbon to remove colour and other impurities.

Get Price

Export - Palm Oil | Soap | Plantation | Refinery

0% import duties on vegetable oil products from Mozambique to the following countries due to bilateral agreements: SADC Agreement: Angola, Botswana, Zimbabwe, Tanzania, South Africa, Namibia, Democratic Republic of Congo, Zambia; Crude Soybean Oil;

Get Price

Vegetable Oil Refinery, Oil Refining Plant, Oil Refining

Vegetable Oil Refining Vegetable Oils Refining is necessary for vegetable oils & fats or animal oils & fats so they can be used for cooking and frying foods. Chemically speaking, oils are Tri-Glycerides or “Fatty-Acid Glycerin Esters” (FAGE). One Glycerin molecule combines with three Fatty-Acid molecules to form one FAGE.

Get Price

Alkali Refining - AOCS Lipid Library

4.1. Neutralisation of crude oil. This method has become established mainly in the USA for refining soybean oil, the so called long mix process. The process is a combination of degumming and neutralization. For the conditioning of the nonhydratable phosphatides, a small quantity of phosphoric or citric acid is added to the crude non-degummed oil.

Get Price

Soybean oil production

Counterflow is used as extraction system because it gives the highest yield. After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food products such as soy protein. The hexane is separated from the soybean oil in evaporators.

Get Price

Soybean Oil Refining & Detailed Soybean Oil Refining Process

The crude soybean oil still contains many oil-insoluble and oil-soluble impurities that needs to be removed. Soybean oil refining including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids, colorants, insoluble matter and gums) and bleaching (with activated earth or activated carbon to remove colour and other impurities.

Get Price

Soybean Oil Refining Process

Degumming / Neutralization Section of Soybean Oil Refining Process. The Crude Soybean Oil is obtained from Oil Mill Plant or from Solvent Extraction Plant.This crude soybean oil contains many undesirable impurities including gums which are mainly phosphatides.

Get Price

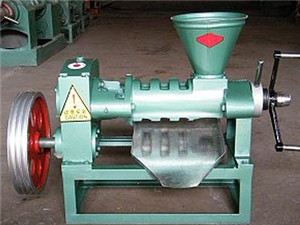

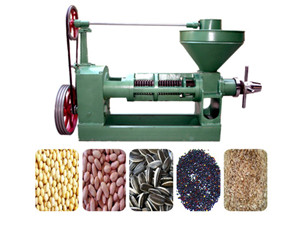

soybean oil extraction plant manufacturer in zimbabwe

mini soybean oil production assembly unit - Oil Mill. Moreover, mini soybean oil production assembly unit can process many other oil seeds, such as peanut kernels, rapeseed, cotton seeds, sunflower seeds, corn seeds, palm kernels, and sesame seeds.

Get Price

2018 First Choice Oil Refinery Plant For Refining

Refining crude soybean oil into refined oil | Wilmar International Through joint ventures, Wilmar also has interests in processing plants in India, Russia, Ukraine, Tanzania, Zambia and Zimbabwe. We crush oilseeds such as soybean, rapeseed, groundnut, sunflower seed,

Get Price

Export - Palm Oil | Soap | Plantation | Refinery

0% import duties on vegetable oil products from Mozambique to the following countries due to bilateral agreements: SADC Agreement: Angola, Botswana, Zimbabwe, Tanzania, South Africa, Namibia, Democratic Republic of Congo, Zambia; Crude Soybean Oil;

Get Price

Soybean Oil Extraction Machinery/Soybean Oil Making

Description Soybean oil is the world's largest production edible oil, henan huatai soybean oil extraction machinery has four workshops: soybean pretreatment , soybean oil extraction plant, soybean crude oil refining plant, soybean refined oil filling.

Get Price

Multiple choice for fats and oils refining

In chemical refining, caustic soda is used to neutralize the free fatty acids in the oil, in a chemical reaction. This more traditional kind of refining normally has the following characteristics: • can be used with a wider variety of crude oils, including soybean, sunflower seed and rapeseed oil • results in a product that is more

Get Price

Technological update on edible oil refining processes

Technological update on edible oil refining processes Vincent Fiers TECHNICAL/SCIENTIFIC CONFERENCE Tuesday 13th May 2014 Istanbul ‐ Turkey. Edible Oil Refining : Where are we now ? 2 Crude Oil Water degumming Alkali ANeutralisation Deod orization Refined Oil refined soybean oil samples. 11 1. Nano‐degumming of crude/WDG

Get Price

Alkali Refining - AOCS Lipid Library

4.1. Neutralisation of crude oil. This method has become established mainly in the USA for refining soybean oil, the so called long mix process. The process is a combination of degumming and neutralization. For the conditioning of the nonhydratable phosphatides, a small quantity of phosphoric or citric acid is added to the crude non-degummed oil.

Get Price

Chemical Refining and Physical Refining of Vegetable Oil

Edible/vegetable oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire oil refining plant process comprises degumming/neutralization, bleaching, deodorization, and winterization.

Get Price

Soybean Oil Extraction Plant, Soybean Oil Extraction Plant

There are 3,377 soybean oil extraction plant suppliers, mainly located in Asia. The top supplying countries are China (Mainland), India, and Hong Kong, which supply 95%, 4%, and 1% of soybean oil extraction plant respectively. Soybean oil extraction plant products are most popular in Africa, Domestic Market, and Southeast Asia.

Get Price

soybean oil extraction plant manufacturer in zimbabwe

Refining crude soybean oil into refined oil | Wilmar. Miscella is distilled and filtered to remove hexane, which is recovered for re-use. The resulting product is crude soybean oil. The crude oil is then refined via three stages: water degumming, chemical refining and physical refining.

Get Price

Chemical Refining and Physical Refining of Vegetable Oil

Edible/vegetable oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire oil refining plant process comprises degumming/neutralization, bleaching, deodorization, and winterization.

Get Price

biggest soybean oil processing in zimbabwe | Edible Oil

Soybean Oil Market Share, Price Trends, Report and. IMARC’s latest study “Soybean Oil Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2018-2023” provides a techno-commercial roadmap for setting up a soybean oil processing plant.

Get Price

REFINING OF SOYA BEAN OIL.pdf | Soybean | Oil Refinery

The crude oil extracted from soyabean needs further treatment to convert it to a bland, stable, nutrition products that is used to manufacture margarine, shortening, salad and cooking oil,

Get Price

Edible oil refining | Cavitation Technologies, Inc.

Edible Oil Refining. Vegetable oil refining facilities process crude oils such as soybean oil, palm oil, rapeseed oil, canola oil, sunflower oil and other specialty oils including: peanut oil, olive oil and cottonseed oil.

Get Price

Vegetable Oil Refinery, Oil Refining Plant, Oil Refining

Chemical Refining In Chemical Refining, Vegetable Oil is treated with caustic lye for separation of free fatty acids from oil. This is a conventional process that can be applied to all oils. A byproduct of alkali refining is soap-stock, which is used for manufacture of low quality washing soap.

Get Price

SOYBEAN OIL

(b) Grade and Quality› Mylog› Commodity

The relationship between crude oil and vegetable oils is as strong as ever. Vegetable oils price is influenced by crude oil price, volatile prices of crude oil put pressure on agriculture and food industry and low prices of crude oil have an impact on vegetable oils used in biodiesel production.

Get Price

Multiple choice for fats and oils refining

Multiple choice for fats and oils refining of crude oils, including soybean, sunflower seed and rapeseed oil • results in a product that is more chemically stable and therefore has a longer shelf life Because soybean oil has a high content of hydratable gums, this is

Get Price

Life Cycle Impact of Soybean Production and Soy Industrial

this study include: soybean growing/agriculture, crushing into crude soybean oil and meal, refining, and methyl soyate production by transesterification, shown in the figure below.

Get Price

Detection of DNA during the refining of soybean oil

The degumming of crude soybean oil causes the removal of DNA, the presence of which is necessary for the detection of genetically modified organisms by polymerase chain reaction (PCR).

Get Price

Crude Oil vs. Soybean Oil - Tastytrade

The Crack Spread is based upon the refining process of Crude Oil (/CL) into Gasoline (/RB) and Heating Oil (/HO). The Crush Spread is based upon the processing of Soybeans into Soybean Meal and Soybean Oil (/ZL).

Get Price

Process technology for refining crude soybean oil – a

Selective optimization of process parameters for refining crude soybean oil was carried out to determine and specify such process parameters as temperature, concentration of reactants, and process duration for adoption in commercial processing.

Get Price

Edible oil refining | Cavitation Technologies, Inc.

Edible Oil Refining. Vegetable oil refining facilities process crude oils such as soybean oil, palm oil, rapeseed oil, canola oil, sunflower oil and other specialty oils including: peanut oil, olive oil and cottonseed oil.

Get Price

Oil : Soy Canada Product Portal (English)

Fully refined soybean oil is produced from fair average quality crude soybean oil that has been solvent-extracted (unless otherwise arranged between buyer and seller). Refining removes essentially all free fatty acids and non-oil substances.

Get Price

Soybean oil refining machine | HRGroup

The main purpose of soybean oil refinery machine is to separate the impurities in the crude soybean oil based on the different characteristics and enhance the stability and purity of oil. Soybean oil refinery machine includes two technologies, physical refining and chemical refining.

Get Price

MSDS - CRUDE DEGUMMED SOYBEAN OIL - LetCO

CRUDE DEGUMMED SOYBEAN OIL is predominantly used in human nutrition after refining and hydrogenation, in form of oil and vegetable fat and margarine. In animal feed soybean oil is energizer.

Get Price

Edible oil refining industry on the verge of closure

Crude soybean oil was to certain extent allowing the refining industry to operate to produce qualitative refined soybean oil to produce cooking oil. With this increase on crude soybean oil duty, the refining industry will not be able to import crude soybean oil. Hence, the refining industry will now at the verge of complete shutdown.

Get Price

Soybean oil refinery plant-|Soybean Oil Extraction Machine

Soybean oil refinery plant includes a series processing procedures as degumming, neutralization, bleaching, deodorization and winterisation. In general there are two methods of soybean oil refining process, one is physical refining and the other is chemical refining.

Get Price

Products / Crude oil refining-oil press machinery,oil

Address The crossing of Taian Road and Zhanhuan Road,Zhandian Industrial Zone,Zhengzhou,Henan Province,China +8615738819095 qie@qiemach

Get Price

Supercritical CO Degumming and Physical Refining of

7004 473 Supercritical CO2 Degumming and Physical Refining of Soybean Oil G.R. List* I J.W. King, J.H. Johnson, K. Warner and T.L. Mounts Food Quality and Safety Research. National Center for Agricultural Utiliz.ation Research. Agricultural Research Service.

Get Price

Oil Refining - AOCS Lipid Library

2. The Refining Process. Refining of crude oil is done to remove unwanted minor components that make oils unappealing to consumers, while trying to cause the least possible damage to the neutral oil as well as minimum refining loss.

Get Price

Steam-refined Soybean Oil: II. Effect of degumming methods

The first paper in this series described the effect of refining and degumming methods on the quality of steam- and caustic-refined soybean oils.

Get Price

Proposal would convert Dickinson oil refinery to renewable

The proposal builds on a pilot project at the Dickinson Refinery, which has involved processing vegetable oil along with Bakken crude to produce a 5 percent renewable diesel blend, Singleton said.

Get Price