Edible / Vegetable Oil Refinery Plant Manufacturers and

Oil refinery plant refers to a series of refining processes that can remove phospholipids, FFA, pigment, off-flavor and other impurities in the oil.Edible oil refinery or vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil. To impart uniform colur by removal of coloring pigments and to get rid of unpleasant smell from

Get Price

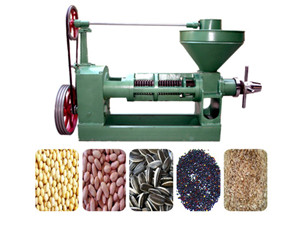

Expeller Pressed Method for Vegetable Oil Extraction

Oil pressing or expeller pressing means a mechanical method which usually use an expeller press to give pressure on vegetables, nuts and seeds by physics pressure to cause the oil to run. It is cost efficient, versatile and chemical-free.

Get Price

Edible Oil Refining | Oil Extraction Machine | Oil Mill Plant

Edible oil refining includes a series processing procedures as degumming, neutralization, bleaching, deodorization and winterisation. In general there are two methods of vegetable/edible oil processing, one is physical refining and the other is chemical refining.

Get Price

Virginia Biodiesel Refinery LLC.

About Virginia BioDiesel. Virginia Biodiesel Refinery is the state of Virginia’s oldest and largest biodiesel production facility. Founded in 2003, we have lead the mid-Atlantic region in providing top quality, locally sourced, sustainable, diesel fuel.

Get Price

Non-edible vegetable oils: A critical evaluation of oil

Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production

Get Price

Oil and Gas Conferences | Petroleum Events | Summit

10th Asia Pacific Congress on Oil and Gas will be held during December 3-4,2018 Bangkok,Thailand. Top petroleum conference anticipate the participants across the globe

Get Price

Bioro Biodiesel Refinery | Cargill

Being part of the integrated Cargill site in Ghent that includes a multi-seed crush plant and a semi-refinery for vegetable oils, means the Bioro biodiesel plant in Ghent is unique.

Get Price

Professional Process of Soybean Oil Production

There are two methods of soybean oil production, one is mechanical way, which is a traditional method that use screw press machine to squeeze oil out from seeds and kernels; the other way is chemical method that extract oil with solvents. Both two oil production methods have advantages and disadvantages. The previous one is natural and healthy but the oil yield is much lower, however, oil

Get Price

Standard Oil

Standard Oil Co. Inc. was an American oil producing, transporting, refining, and marketing company. Established in 1870 by John D. Rockefeller and Henry Flagler as a corporation in Ohio, it was the largest oil refinery in the world of its time. Its history as one of the world's first and largest multinational corporations ended in 1911, when the United States Supreme Court, in a landmark case

Get Price

Fruit & Vegetable Process Plant - Coconut Milk Processing

SSP Private Limited - Manufacturer and exporter of Fruit & Vegetable Process Plant, Coconut Milk Processing Plant, Fruit Juice Powder Plant, Fruit Juice Concentrate Plant, Aroma Recovery Plant, Multi-Fruit Processing Plant, Tomato Paste Plant, Ketchup Plant from India.

Get Price

Manufacture of Vegetable oil refining methods_Oil Refining

manufacture of Vegetable oil refining methods,Vegetable oil refining process usually includes the following sections: degumming and deacidification, decolorization, deodorization and dewaxing. The process of removing these impurities after oil extraction section and

Get Price

Edible / Vegetable Oil Refinery Plant Manufacturers and

Oil refinery plant refers to a series of refining processes that can remove phospholipids, FFA, pigment, off-flavor and other impurities in the oil. Edible oil refinery or vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil.

Get Price

Vegetable oil refining

Vegetable oil refining is a process to transform vegetable oil into biofuel by hydrocracking or hydrogenation. Hydrocracking breaks big molecules into smaller ones using hydrogen while hydrogenation adds hydrogen to molecules. These methods can be used for production of gasoline, diesel, propane, and other chemical feedstock.

Get Price

Chemical Methods Vegetable Oil Refinery Processing Line

Edible/vegetable oil refining is a step by step hroilrefinerymachine removes The entire oil refining plant process comprises degummingeutralization, bleaching, deoderization, and winterization. Chemical refining Apart from chemical refining, physical refining is another method that used for edible oil refining.

Get Price

Impurities in Crude Oil and Refining Methods

Crude oil (raw oil) is unrefined vegetable oil which is generally obtained from oilseeds pressing (squeezing) or solvent extracting, without refining. The main component of crude oil is a mixture of fatty acid triglycerides, commonly known as neutral oil.

Get Price

Electrocoagulation of vegetable oil refinery wastewater

Electrocoagulation with aluminum electrodes was used to treat the vegetable oil refinery wastewater (VORW) in a batch reactor. The effects of operating parameters such as pH, current density, PAC (poly aluminum chloride) dosage and Na 2 SO 4 dosage on the removal of organics and COD removal efficiency have been investigated.

Get Price

Oil Refinery Plant|Customized Edible Oil Refining Process

In addition to various levels of edible oil, there are base oil, drying oil, paint oil, pyrolysis oil, hydrogenated oil, salad oil, cooking oil, vegetable shortening and margarine, etc. Customized oil refining process will be offered to meet the quality requirements of different oil.

Get Price

Chemical Methods Vegetable Oil Refinery Processing Line

Edible/vegetable oil refining is a step by step hroilrefinerymachine removes The entire oil refining plant process comprises degummingeutralization, bleaching, deoderization, and winterization. Chemical refining Apart from chemical refining, physical refining is another method that used for edible oil refining.

Get Price

Vegetable Oil Refining Plant — "Sodrugestvo" Group of

Physical refining method (alkali-free refining with combined processes for removal free fatty acids, odorising substances and oxidation products) The combination of these technological processes allows for processing of vegetable oil of different quality, including non-refined oils from different seeds

Get Price

Edible / Vegetable Oil Refinery Plant Manufacturers and

Oil refinery plant refers to a series of refining processes that can remove phospholipids, FFA, pigment, off-flavor and other impurities in the oil. Edible oil refinery or vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil.

Get Price

Chapter 5 : Processing and refining edible oils

Rural refining of oil-bearing plants can produce fats and oils of good quality which provide needed energy and fat soluble vitamins. Commercial refining produces fats and oils that can be of high quality and have the characteristics of bland taste, clear colour, good keeping quality and frying stability.

Get Price

Advanced Vegetable Oil Processing and Its Steps

Vegetable oil processing is a complicated oil processing process. For different oil seeds the production process is diffent too. For different oil seeds the production process is diffent too. Vegetable oils are being processed by grinding, cooking, expelling and pressing, or by

Get Price

Impurities in Crude Oil and Refining Methods

Crude oil (raw oil) is unrefined vegetable oil which is generally obtained from oilseeds pressing (squeezing) or solvent extracting, without refining. The main component of crude oil is a mixture of fatty acid triglycerides, commonly known as neutral oil.

Get Price

Vegetable oil refining

Vegetable oil refining is a process to transform vegetable oil into biofuel by hydrocracking or hydrogenation. Hydrocracking breaks big molecules into smaller ones using hydrogen while hydrogenation adds hydrogen to molecules. These methods can be used for production of gasoline, diesel, propane, and other chemical feedstock.

Get Price

Chemical Methods Peanut Oil Refinery System

Chemical Methods Peanut Oil Refinery Project. Chemical Methods Peanut Oil Refinery Project . Peanut oil, also known as groundnut oil or arachis oil, is a mild-tasting vegetable oil derived . peanut allergy. Since the degree of processing for any particular product is often unclear, avoidance is prudent.

Get Price![[pdf]<h3>9.11.1 vegetable oil processing - us epa](/seedoil/47.jpg)

[PDF]9.11.1 Vegetable Oil Processing - US EPA

9.11.1 Vegetable Oil Processing 9.11.1.1 General1-5 The method used depends upon the end use of the Vegetable Oil Refining - Crude oil is typically shipped for refining to establishments engaged in the production of edible vegetable oils, shortening, and margarine. Crude vegetable oils contain small amounts of naturally

Get Price

Vegtetable Oil Processing and Products of Vegetable Oil

Vegtetable Oil Processing and Products of Vegetable Oil/Biodiesel. New methods in vegetable oil refining and processing; Latest methods in bleaching, neutralization, interesterification and deodorization of major vegetable oils and vacuum systems and much more; Who Should Attend. This short course is a must attend for anyone involved in

Get Price

Vegetable oil

Vegetable oils, or vegetable fats, are fats extracted from seeds, or less often, from other parts of fruits. Like animal fats, vegetable fats are mixtures of triglycerides. Soybean oil, rapeseed oil, and cocoa butter are examples of fats from seeds. Olive oil, palm oil, and rice bran oil are example of fats from other parts of fruits. In common usage, vegetable oil may refer exclusively to vegetable fats which are liquid at

Get Price