Large scale crude oil extraction machine is mainly used in the middle and large scale oil mill plants for vegetable and biodiesel oil processing. These large oil presses are generally divided into two kinds: oil press for hot pressing, and low temperature oil press for cold pressing. The large scale oil press extraction machines we supply is suitable for extraction of vegetable oils from oil bearing seeds and nuts, such as rapeseeds, grounnut, sesame seeds, cottonseeds, soybean seeds, corn germ, copra, sunflower seeds, etc.

For the whole process of crude oil extraction machine, Please see below.

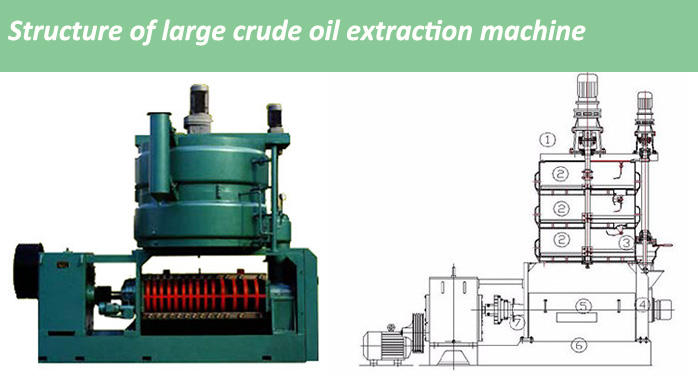

The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heated up and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage, it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressing worms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oil reservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction, beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when once the amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observe the feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirement of supervision and greatly saving labor.

Main Parts Of The Automatic Oil Press Machine

1.screw shaft

2.feeder

3.pressing cage

4.oil pan

5.squeezing bolt

6.vacuum oil filter system

7.electric control system

8.heating ring

Operate Processing Of The Automatic Oil Press Machine

1.stir-fring the seed

2.feed in the oil seed

3.pressing the seed in the pressing chest

4.oil drip on the oil pan from the squeezing bolt

5.then oil inflow the vacuum oil filter pan by the vacuum system

6.then pure oil come out of the filter

7.ready

Advantage Of The Automatic Oil Press Machine

1. Energy Saving:The electric power can be reduced by 40% under the same output. For example, the machine can save 6 kilowatt at an average of one hour. In that case, it could save about 30 RMB per day.

2. Labor Saving:60% labor can be saved under the same output. One or two person can organize the production. It can save about 40 RMB of labor cost every day.

3. Widely Usage:The machine is multi-function. It can process more than 20 kinds of oil crops, such as, peanut, linseed, sesame, rapeseeds, sunflower, cottonseeds, soybean, etc.

4. Oil Pure:Vaccum filter can filter the residue and ensure the oil quality. The oil can meet the standard of health quarantine.

5. Small Area Covering: 10 ~ 20 m2can meet the production needs.