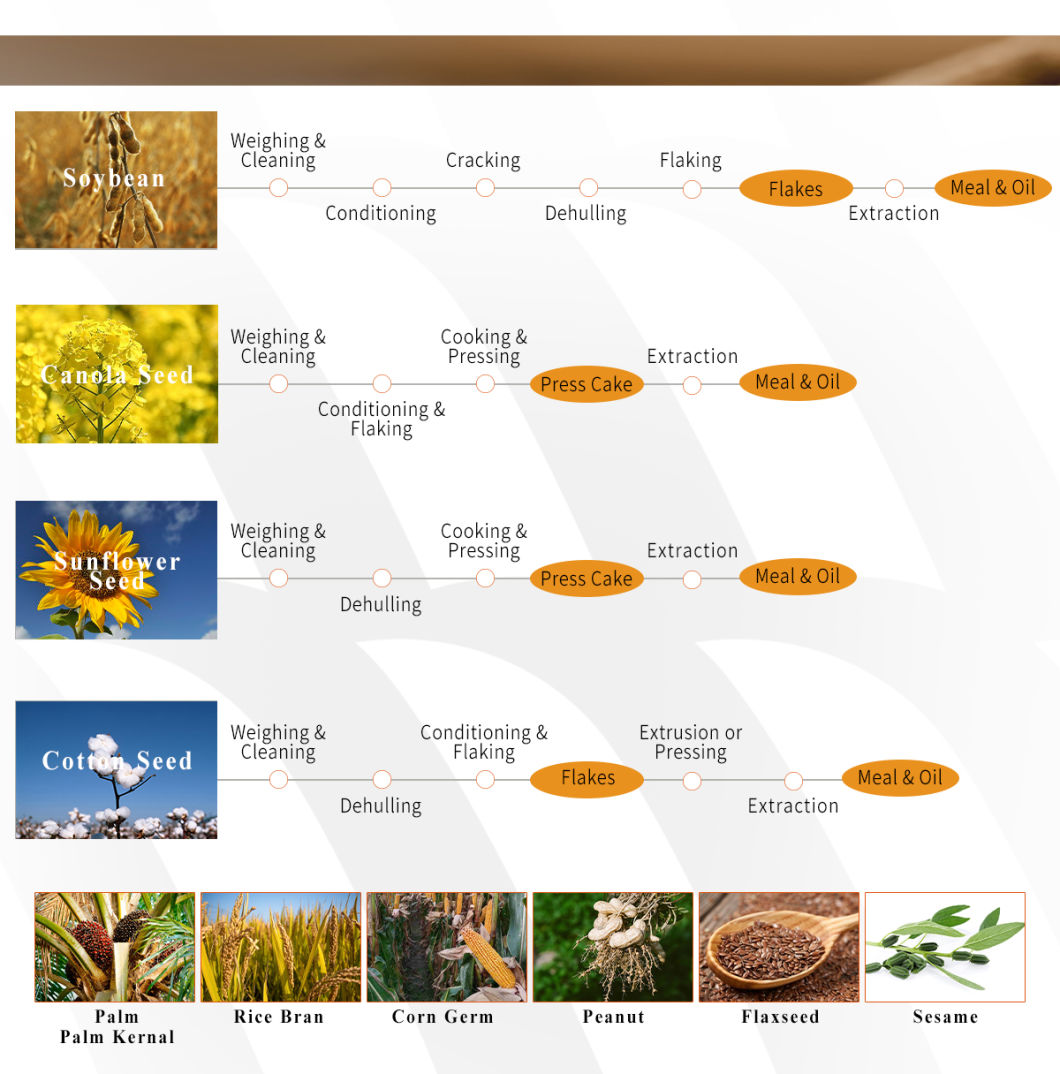

Oilseeds preparation aims to transform oilseeds into high quality flakes, or extruded oilseeds, or pressed cakes desirable for optimal extraction. Myande provides targeted oilseed preparation processes (cleaning, cracking, dehulling, conditioning/cooking, flaking, expanding, crushing, pelletizing, and so on) based on different properties of different oilseeds and clients’ individual requirements.

Myande also provides equipment and technical solutions for meal classification and grinding and adjustment of meal protein content.

Myande oilseeds preparation solutions give full consideration of environmental protection needs, which include dust emission control, heat recovery, minimizing energy consumption, high integration of automation and process, reducing labour intensity, and stable parameters of final products.

1,Capacity: as required

2,Residual oil in the cake: about 8% ;

3,Pressing temperature: 105ºC-115ºC ;

4,Water Content: 5%-7%

Oil cottonseed special oil press: we use our company’s self developed oil cottonseed screw oil press HP260, and the residual oil of a pressed cake is around 7%. The biggest feature of this machine is less energy consumption and less floor area, which is the first choice for oil cottonseed oil making.Oil seed special oil press: we use our company’s self developed oil seed screw oil press HP260, and the residual oil of a pressed cake is around 7%. The biggest feature of this machine is less energy consumption and less floor area, which is the first choice for oil cottonseed oil making.

Main machine list:

| No | Equipment Name | Qty |

| 1 | Cleaning screen | 1 |

| 2 | De-stoner | 1 |

| 3 | Dust collector | 1 |

| 4 | Bucket elevator | 3 |

| 5 | Crushing machine | 1 |

| 6 | Flaking machine | 1 |

| 7 | Steam-cooking pot | 1 |

| 8 | Screw conveyor | 1 |

| 9 | Screw oil press | 1 |

| 10 | Vibrating filter | 1 |

| 11 | Steam distributor | 1 |

| 12 | Electricity & Control | 1 |

1.Cleaning. Use magnetic selector to remove metal impurities and remove other impurities with cleaning screen, specific gravity stoner and dust remover. If its sunflower seeds for oil usage, shelling is not required; if for edible type, shelling is required.

2.Crushing. Use crusher to crush sunflower seeds into pieces so as to get smaller particle size for flaking.

3.Flaking. Roll sunflower seeds particles into flakes with flaking roll, so as to break its cellular structure and then separate oil easier when extracting.

4.Cooking. Through adjusting sunflower seeds flakes to suitable moisture and temperature to break internal structure of sunflower seeds so as to separate oil from oilseeds.

5.Oil pressing. Use oil press to press cooked flakes through physical mechanical press.