In a typical edible oil processing plant oil is extracted from the seed first using mechanical extraction (expeller press) process followed by chemical extraction (hexane extraction) process. By using both methods less than 1% of the oil is left in the meal. Then the left out residual meal is sold as an animal feed raw material. Following are the steps involved for the processing of vegetable oil:

Step 1: Harvesting of Oil Seeds

Seed is planted and harvested as with any other crop. This is followed by the cleaning process, which removes unwanted materials such as soil and other seeds from the harvest. In some cases, it is preferable to shell the seed, removing hulls for a better-quality final product.

Step 2: Processing

At this point, if the seed is large, the seed is crushed or broken up into smaller pieces. These uniform pieces are then conditioned by heating before being pressed for oil. The two products of this process are the raw pressed oil and the press cake, which is the compressed dry material of the seed. The raw oil is filtered before moving on to the final steps.

Step 3: Solvent Extraction

Pressed cake is flaked and broken down for additional oil extraction. The flakes are ground up and mixed with hexane to produce a slurry, which is heated. During heating, the hexane evaporates, and is collected for further use. While being heated, the meal releases the remaining oil, which is mixed with a small amount of hexane that did not evaporate.

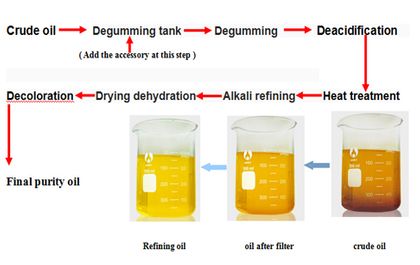

Step 4: Refining

It is a combination of the following process steps for producing an edible oil with characteristics that consumers desire such as bland flavor and odor, clear appearance, light color, stability to oxidation and suitability for frying:

- Degumming: A pretreatment process applied to seed oils to reduce the phosphorus content. It is a two-step process with addition of water and/or acid to hydrate phospholipids. The phospholipids are subsequently removed by centrifugation.

- Neutralization: The purpose of neutralization is to reduce the concentration of free fatty acids to a maximum of 0.10% with the use of a diluted alkali solution, typically sodium hydroxide. This process can be applied batch-wise in stirred vessels and continuously by means of centrifuges. After alkali treatment, the oil is washed with hot water or treated with silica to reduce the residual soap level in the neutralized oil.

- Bleaching: The main purpose is to remove residual soap, pigments, and oxidized components. In this process, bleaching earth (activated clay and/or silica) is added to the oil as absorbent. The earth and absorbed impurities are subsequently removed by filtration. Addition of activated carbon in the bleaching process will also reduce the polycyclic aromatic hydrocarbon level. An acid pretreatment before bleaching earth addition will improve the removal of phosphorous (max 30ppm) and/or metals during the bleaching process.

- Deodorization: Under high vacuum the oil is heated to 180–240°C and brought in contact with stripping steam to remove volatile components and to create an odorless oil with a bland taste and increased storage stability. Also, free fatty acids can be removed during deodorization, at increased temperatures (220–270°C).

Edible oil production plants will be designed specifically according to characteristics of raw materials to be used in production. Impurities contained in the raw material used directly affect properties of machines to be used in the cleaning system.

The first step in the production of edible oil is milling and screening. After this stage, the main cleaning process is carried out, and extraction is done to obtain oil. Impurities in obtained crude oil are removed by the refining process.

The machines to be used in all of these stages are determined according to many parameters such as capacity, raw material, desired end product quality, facility layout plan.

Edible oil is often used in home cooking, soap and industrial food manufacturing worldwide and also it is the basic source of unsaturated fats and vitamin E in human diets. Also, edible oil is used in many areas such as biodiesel with the development of technology.